-

Hi-tech glass industries, Chedichery,

Po. Peruvalath Paramb, Irikkur -

Call Us +91 799 414 7474

-

Mail Us hightecknr@gmail.com

Hi-tech glass industries, Chedichery,

Po. Peruvalath Paramb, Irikkur

Call Us +91 799 414 7474

Mail Us hightecknr@gmail.com

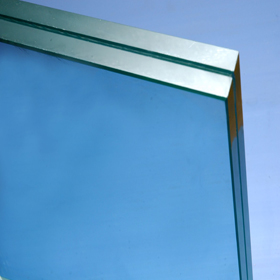

Insulating glass (IG), more commonly known as double glazing (or double-pane, and increasingly triple glazing/pane), consists of two or three glass window panes separated by a vacuum or gas filled space to reduce heat transfer across a part of the building envelope. Insulating glass units (IGUs) are manufactured with glass in range of thickness from 3 to 10 mm (1/8″ to 3/8″) or more in special applications. Laminated or tempered glass may also be used as part of the construction. Most units are produced with the same thickness of glass used on both panes but special applications such as acoustic attenuation or security may require wide ranges of thicknesses to be incorporated in the same unit.

Insulating glass is a very effective way to reduce air-to-heat transfer through the glazing. When used in conjunction with low-E and/or reflective coatings, IG units perform even better for conserving energy and complying with local codes. The most common configuration of IG units for commercial building is a 6 mm lite, 12mm of air space and a 6mm lite.

As low-E coatings have become better at reducing air-to-air heat transfer, spacer technology has become the focus of incremental thermal improvements. Typical commercial spacers are composed of formed aluminum filled with desiccant to absorb any residual moisture inside the IG unit, thus reducing potential condensation. While this is a structurally strong material, the aluminum-to-glass contact point is a very efficient thermal conductor and can increase the potential for temperature differential between the center of glass and the edge of glass, which can lead to condensation and reduces the unit’s overall U-value.

SunGuard coatings provide substantial improvements – up to 50 percent in U-values and solar heat gain coefficients compared to uncoated insulating glass units. In addition, new “warm-edge” spacer materials can lower the U-value further.